Everything about ATEX

2. What does the ATEX logo look like?

3. What are the most well-known ATEX directives?

4. For which industries is ATEX important?

5. For which products is ATEX important?

6. What are the explosion protection directives?

7. What types of ignition protection are available?

About Auer Signal

Auer Signal is a global leading manufacturer of signaling technology, operational in 70+ countries. The company produces stack lights, visual-, audible-, visual-audible and explosion proof signaling devices.

Discover Signaling Devices NOW!

What is ATEX ?

The word "ATEX" is derived from the term "ATmospheres EXplosibles". The term ATEX is the widely used synonym for the explosion protection directives in the European Union. The directive currently includes the following two directives in the field of explosion protection:

- Product Directive 2014/34/EU

- Operating directive 1999/92/EC

What does the ATEX logo look like?

The hexagonal ATEX logo with the letters E and X will be affixed to the equipment together with other equipment markings after conformity validation has been completed. The ATEX symbol proves two conditions:

- A type was tested by a conformity assessment body within the EU.

- The routine test showed that the type and the device match.

If thoses two conditions are met the product is atex certified. The atex logo is proof of the conformity of the product.

What are the most well-known ATEX directives?

In order to avoid explosion hazards, there are corresponding protection regulations in the form of laws, ordinances and standards which are intended to ensure a high level of safety. With the current product directive 2014/34/EU, the EU has created the ATEX directive. This explosion protection directive, which is derived from the French atmosphère explosible, has unified the most diverse previously existing regulations.

In addition to the Product Directive 2014/34/EU (aimed at manufacturers of products), there is also the Operation Directive 1999/92/EC (aimed at the requirements for users). Both explosion protection directives were published earlier under other product directives (e.g. ATEX 95).

Product Directive ATEX 2014/34/EU

In 1994, the Product Directive 94/9/EC was published for the first time. The aim was to "approximate the laws of the European Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres". Initially, this explosion protection directive had the working title ATEX 100a, as it was based on Article 100a of the first Treaty establishing the European Community. Due to subsequent renumbering of the treaty, this designation changed, and the product directive was given the name ATEX 95. In 2014, in the course of the "harmonization of the legal provisions of the member states for equipment and protective systems for use in potentially explosive atmospheres", it was replaced by the product directive 2014/34/EU and has always been bindingly valid in all EU member states and accordingly has the character of law.

ATEX 100a = ATEX 95 = Product Directive 94/9/EC = 2014/34/EU

The ATEX 95 Product Directive covers all equipment that has its own potential source of ignition and can therefore cause a possible explosion.

Protective systems or protective devices that are intended to prevent or contain an explosion and are operated as a separate autonomous unit are also covered by this product directive. Components that are necessary for the safe operation of the equipment and protective systems but do not constitute an autonomous functioning unit, such as ball bearings, couplings, capacitors or batteries, are also subject to this directive. The ATEX 95 product directive applies to all electrical, non-electrical and mechanical equipment used in potentially explosive atmospheres, as well as to the same equipment and protective systems that are located outside potentially explosive atmospheres but must ensure safe functioning for explosion protection.

OPERATING DIRECTIVE 1999/92/EC

The ATEX Directive focuses on the user of a machine, plant or device. The operating line is derived from the former explosion protection guidelines ATEX 118a and ATEX 137.

ATEX 118a = ATEX 137 = Operating Directive 1999/92/EC

It is based on Article 153 of the Treaty on the Functioning of the European Union (TFEU) and is intended to take into account and improve the occupational safety and health protection of workers who are at risk from explosive atmospheres at the workplace.

ATEX PROTECTIVE MEASURES

In order to determine protective measures and to select protective means for the protection of the employee, the operator must take the following points into account in the risk assessment regarding explosive atmospheres:

- minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres and criteria for selecting equipment and protective systems

- The probability, duration and assessment of the occurrence of explosive atmospheres including preventive and protective measures against explosions

- The probability of the presence, activation and effectiveness of ignition sources, including electrostatic discharges

- The plant, the substances used, the process and their possible interactions

- Classification of areas (ATEX zone classification) in which explosive atmospheres may be present

- Warning signs to identify areas where explosive atmospheres may occur

- The extent of the expected effects of an explosion

- Duty of coordination

- Creation of an explosion protection document

MARKING OF ATEX DEVICES

The Product Directive 2014/34/EU not only specifies the basic health and safety requirements, but also the conformity assessment procedure for products and equipment that can be used in hazardous areas. All equipment, protective systems and installations that fall under this product directive and are placed on the market must therefore be marked as follows:

- Name and address of the manufacturer

- CE-Certificate and, where appropriate, the identification number of the notified body involved

- Series name and type

- Serial number or fabrication number

- Year of manufacture

- Device group and category

In addition, the product must have a European declaration of conformity, which describes the procedures for the required health and safety requirements and whether these could be met in the course of the conformity test. Furthermore, the product must be accompanied by operating instructions.

DIFFERENCES BETWEEN THE PRODUCT DIRECTIVE 2014/34/EU AND THE OPERATION DIRECTIVE 1999/94/EC

| Product Directive 2014/34/EU (ATEX 95) | Operation Directive 1999/94/EC (ATEX137) |

| makes demands on manufacturers | makes demands on users |

| ATEX category classification | ATEX zone classification |

| isk and ignition source analysis of devices | Hazardous area analysis of operating areas |

| Declaration of conformity | Explosion protection document |

For which industries is ATEX important?

ATEX certified applications (including explosion-proof signal devices) are important for all branches and industries where flammable substances may be generated.

In the petrochemical or chemical industry, flammable substances such as gases or liquids are further processed. These are highly flammable and must not cause an explosion in an emergency or incident by using a signal device.

In metal industries, explosive metal dusts are generated during the processing of raw materials, especially during the treatment of light metal. ATEX certified applications must be used here as well.

Refineries, such as petroleum or biorefineries, can also generate explosive atmospheres. During the processing of the raw materials, explosive biogas or hydrocarbons can escape, among other things, making the environment a potentially explosive area.

But also in other industries, such as the wood processing industry, flammable dust mixtures are generated during processing which can cause an explosion in case of emergency.

For which products is ATEX important?

ATEX is particularly important for those products used in potentially explosive atmospheres that have a potential ignition source. This creates the risk of a possible explosion. In addition, those products are affected that are intended, individually or in combination, for the generation, transmission, storage, measurement, control and conversion of energies and for the processing of materials.

The ATEX directive for products covers not only the equipment, but also components and protective systems. Products include, for example, machines (including filling machines and screening machines), motors and warning systems (e.g.optical and acoustic signal devices) or special applications for an ATEX switch cabinet.

go to signaling devices with ATEX explosion protection

What are the explosion protection classifications?

For a concluding ATEX certification of a device, it is necessary that the manufacturer carries out a mandatory evaluation of the ignition hazards that can be assumed from his device. After completion of the determination and evaluation, the manufacturer divides the equipment into predefined categories.

WHICH ATEX CATEGORIES EXIST?

The classification is based on the Product Directive 2014/34/EU and is divided according to risk area and equipment group and category. There are two device groups: Group I and Group II.

ATEX Explosion Group I categorizes all equipment used in mines or underground mines and their surface installations that may be endangered by mine gas and/or combustible dusts.

ATEX Explosion Group II applies to equipment for use in all other areas endangered by a potentially explosive atmosphere. These can be, for example, drilling platforms, refineries or chemical and pharmaceutical plants.

In addition, the ATEX explosion groups are subdivided according to the frequency of occurrence of an explosive atmosphere. Within Group I, there are further subcategories 1 and 2. Group II has the subcategories 1, 2 and 3, where subcategory 1 has a very high level of safety (permanent danger of the formation of an explosive atmosphere), subcategory 3 a normal level of safety (rare danger of the formation of an explosive atmosphere).

Depending on the level of safety, an EU type examination and quality assurance of production or individual testing must be carried out, or for category 3, only an internal production control must be demonstrated.

The following table shows the ignition hazards for equipment group II:

| ATEX Device category | Ignition sources on/in the device/machine/plant |

| Category 1 | No ignition sources, also not in case of rare unexpected operational disturbances. This category also applies to protective systems. |

| Category 2 | No ignition sources, even under normal conditions to expected operational disturbances. |

| Category 3 | No ignition sources during normal operation. |

Depending on the type of hazardous area, the ATEX equipment categories are further identified by a code letter. For example, for Category II equipment, the hazardous area for gases, vapours or mist is marked with the letter "G" on the one hand and the hazardous area for dusts with the letter "D" below the equipment category on the other. For equipment of ATEX explosion group I, the code letter "M" is used for methane. Thus, for the ATEX equipment categories, the following table provides further details:

| Danger | Category | Risk |

| Gases, vapors or mist | 1G | Permanently, frequently or long-term |

| Gases, vapors or mist | 1G or 2G | Occasionally |

| Gases, vapors or mist | 1G or 2G or 3G | Rarely; if, then only briefly |

| Dust | 1D | Permanently, frequently or long-term |

| Dust | 1D or 2D | Occasionally |

| Dust | 1D or 2D or 3D | Rarely; if, then only briefly |

| Methane | M1 or M2 | Mining |

In each EU member state, there is one or more notified bodies which can independently control or carry out the corresponding requirements or procedures of the device to prove compliance with the Product Directive 2014/34/EU. In case of conformity with the regulations of the product directive, a EU type examination certificate issued. Once the device has passed the conformity assessment procedure and all requirements for the application of a CE mark are met, it can be successfully placed on the market.

WHAT ARE THE ATEX ZONE CLASSIFICATIONS?

In addition to a division into categories, there is also a division into zones. According to the Product Directive 2014/34/EU, a potentially explosive atmosphere is defined as a room or area that may become explosive due to local and/or operational conditions in the atmosphere. A potentially explosive atmosphere is created by mixing air with flammable gases, vapours, mists or dusts under atmospheric conditions in which, after ignition has occurred, the combustion process spreads to the entire unburned mixture.

The Operating Directive 1999/94/EC or ATEX 137 regulates the division of plants in which a potentially explosive atmosphere may occur into individually endangered zones. In return, the Product Directive 2014/34/EU or ATEX 95, on the other hand, contains a division of equipment into groups and categories. From this combination it is derived which equipment groups and categories may be used in which zone. The classification of areas is based on the frequency and duration of the occurrence of an explosive atmosphere and includes gas, vapour or mist as well as the three-zone concept for dust.

The following ATEX certified zone classifications apply to areas where there is a risk of explosion due to flammable or combustible gases, vapours or mist in accordance with the German Hazardous Substances Ordinance:

| ATEX Zones | Ignition sources on/in the device/machine/plant |

| Zone 0 | An area in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously, frequently or for long periods. |

| Zone 1 | An area in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist occurs only occasionally during normal operation. |

| Zone 2 | An area in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation or is likely to do so only for short periods. |

The following ATEX zone classifications apply for areas that are at risk of explosion due to combustible dusts in accordance with the Hazardous Materials Ordinance:

| ATEX Zones | Degree of hazard with combustible dusts |

| Zone 20 | An area in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, frequently or for long periods of time |

| Zone 21 | An area in which an explosive atmosphere in the form of a cloud of combustible dust in air occurs only occasionally during normal operation |

| Zone 22 | An area in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation or is likely to do so only for short periods. |

In the North American „division“-system only two probabilities of ignitable mixtures are defined:

- Division 1 (comparable with zone 0 and 1)

The ignitable gases, vapors or dust particles occur permanently or only temporarily during normal operation. - Division 2 (comparable with zone 2)

The ignitable mixtures probably do not occur during normal operation (rarely and if they do, then only for a short time)

What types of ignition protection are available?

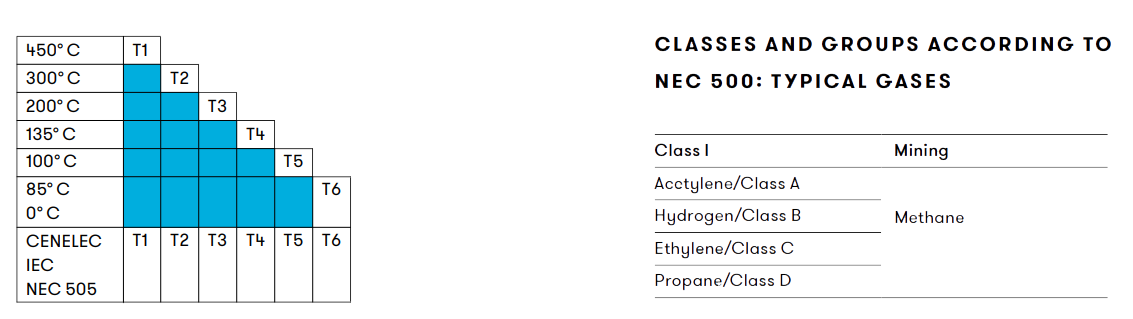

Ignition protection types are used to prevent ignition in environments with explosive atmospheres by preventing them from reaching impermissibly high temperatures. The ATEX temperature classes and the maximum allowable surface temperature of the equipment are defined according to CENELEC/IEC/NEC 505 and NEC 500.

The types of protection differ according to the type and function of the equipment and the probability of the occurrence of an explosive atmosphere.

Depending on the field of application, the types of protection of electrical and non-electrical explosion-proof devices are classified according to DIN 60079. Here, as in the case of the zoning, a distinction is made between gas and dust explosion hazardous areas. Ignition protection types for non-electrical devices are defined in the DIN EN 13463 and DIN EN ISO 80079 series of standards. The correct designation of an explosion-protected device is also explained with the corresponding explanation of the individual abbreviations.

In the following download, the different types of protection are shown in tabular form.

How are ATEX devices being certified?

In order for the manufacturer to be allowed to sell the device in accordance with the ATEX Product Directive, it must first undergo a conformity assessment procedure with associated regulations, standards and directives. This procedure is necessary to obtain ATEX certification in accordance with the ATEX directives.

ATEX CERTIFICATION

First, the manufacturer must know which certification procedure applies to him or the product, as this depends on the zone in which the product is to be used. The ATEX equipment category is also an important factor in the conformity assessment procedure.

This results in the following possibilities for ATEX certification:

- For products of ATEX equipment category 3, the manufacturer can declare ATEX conformity under his own responsibility in compliance with the "Internal production control according to Annex VIII" of the directive.

- For products of ATEX equipment category 2, a distinction is made between electrical and non-electrical products.

Electrical products must be tested by a notified body. Also, the manufacturing process has to be tested by the notified body. This has to be organized by the manufacturer.

If, on the other hand, the product is a non-electrical product, the manufacturer is obliged to lodge the technical documentation with a notified body for at least 10 years and to carry out the "internal production control pursuant to Annex VIII" of the Directive under his own responsibility.

- For products of equipment category 1 the same requirements for the approval procedure apply as for electrical products of equipment category 2: Testing of the product by a Notified Body with monitoring of the manufacturing process.

As proof of the conformity of his product by a notified body, the manufacturer receives a certificate which serves as proof of conformity. This certificate gives the manufacturer access to worldwide markets and thus a competitive advantage. Defined standards and uniform test protocols make it possible to reduce the time to ATEX approval as well as the costs associated with market introduction.

Once the conformity validation has been completed, the equipment may be marked with the ATEX logo.

What is IECEx?

IECEx is an international procedure for the certification of electrical equipment used in potentially explosive atmospheres. IECEx stands for "International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres" or "International procedure for the certification of electrical equipment used in hazardous areas".

The objectives of the IECEx procedure of the IEC (International Electrotechnical Commission) are to facilitate international trade in equipment and services for use in potentially explosive atmospheres by harmonising standards while maintaining the required level of safety.

The IECEx system facilitates access to international markets, as the certificate is recognized in all participating countries after a transitional period. Similar to ATEX, IECEx has regulations that classify environments into specific hazard classes. The following three standards are relevant:

- IEC 80079-0

- IEC 80079-18

- IEC 80079-31

After testing the device and recognition of the quality assurance system (QAR) introduced, a Certificate of Conformity (CoC) is issued for the manufacturer. During the transition period, issued test reports, so-called ExTRs (Explosion Protection Test Reports) can be used as a basis for the required national certifications. As with ATEX, certificates are also issued by external certification bodies for IECEx.

()

()